Product Description

Test indicator

Before the introduction of modern geared dial mechanism, use of a single

lever or lever systems were used in test

indicators. The difference lied in the range and precision of these devices

which were not as good as the modern ones.

The typical range was 10/1000 inch to 30/1000 inch, and precision of 1/1000

inch. At the time, a common single lever

test indicator was the Starrett (No 64) and systems of lever were made by

Starrett (no 564) [2] and Lufkin (No 199A) [3]

and another company called Ideal Tool Co.

Digital indicator

The dial (clock face) such as in the clock has been ousted by

the digital display indicators like LCDs and the clockwork

has been replaced by linear encoders. Of course digital indicators have its

advantages and are hence more prominently

used. Recording and transmission of data electronically to a computer

through an interface (RS 232 or USB) is an easier

work. This enables Statistical Process Control (SPC), where a computer

tracks the measurement in a database table or a

spreadsheet to interpret the result through statistical analysis

Dial test indicator tips

Dial test indicators have tips that swing in an arc, whereas the previous

models had spherical tips that were plunging

linearly. As the tips moves through the arc, the point contact is made that

gives steady measurements. Consistent offset

distance from the ball surface to the center point, in spite of any ball

contact angle with the measured surface gives

consistent measurement result. The spherical diameters offered are available

in the standard size of 1mm, 2mm, and 3mm.

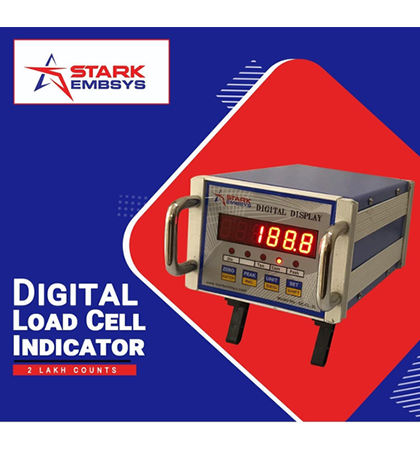

Specifications

| Model |

SE 101 |

| Brand |

Stark Embsys |

| Application |

Weights & Measures, Automation, Testing Machines, SPM's,

Calibration Systems |

| Display |

6 Digits, High Glow Red Display |

| Size |

96 mm x 192 mm x 160 mm |

| Counts |

Up to + 50,0,000 Stable Reading |

| Input Sensors |

Load Cell / Torque Transducer / Pressure Transducer / LVDT |

| Outputs |

2 Relay, 0 - 10 Volt (Optional), RS 232 (Optional) |